Mixed Fixtures Are More Common Than Ever

Gone are the days of running just one type of fixture for every job. In modern CNC shops, you often need to switch between different fixture types—vises, chucks, and custom tooling plates—all while keeping your setup time to a minimum.

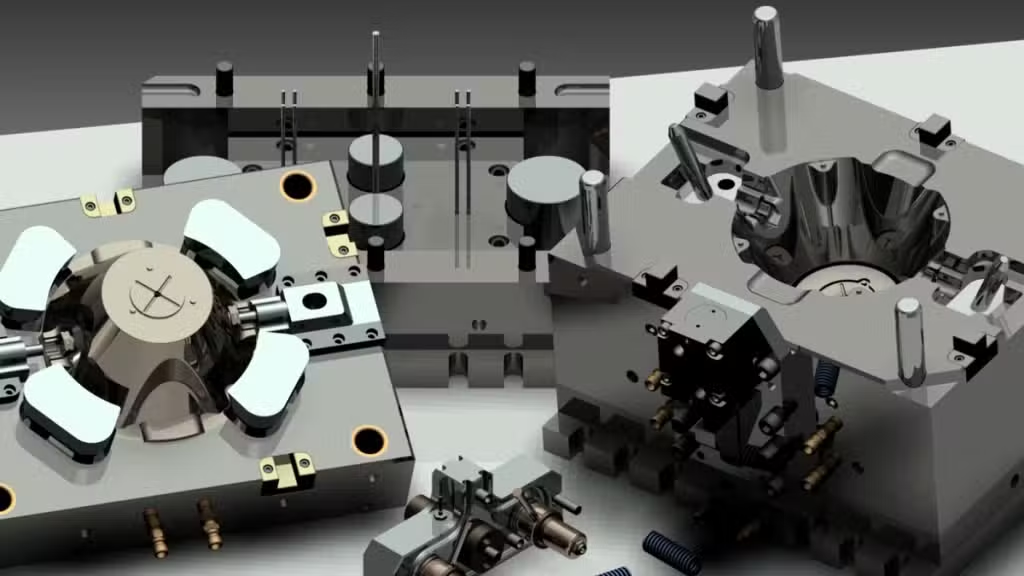

That’s where a manual 8-hole master plate comes in. Designed to support 52×52mm and 96×96mm locating patterns, this quick-change system allows shops to run mixed fixtures while maintaining high repeatability and reducing the need for constant re-indicating.

What Is an 8-Hole Master Plate?

At its core, the 8-hole master plate is a manual zero-point system that provides a stable base for various fixture types. The plate features 52×52mm and 96×96mm locating holes that match the most common fixture and hydraulic vise sizes. This dual-pattern system makes it easy to switch between fixtures without disrupting the entire machining process.

The main benefits:

- Quick fixture swaps: No more spending time aligning or indicating between setups.

- High repeatability: Achieve consistent results with 0.005mm repeatability.

- Flexible fixture compatibility: Supports both small and large fixtures (52mm and 96mm).

How Does It Work in Real Shops?

In real-world scenarios, shops often need to switch between different fixture types based on part size, material, and machining requirements. With the 8-hole master plate, you can easily switch between D52 vises, D96 vises, and three-jaw chucks, all while using the same base system.

The key advantage here is minimized interference. When you can quickly switch between fixture types, you reduce the need to reconfigure or adjust parts in the middle of a job, which directly translates to reduced setup times.

Features of the 8-Hole Master Plate

Xindian’s 8-hole master plate comes with a few standout features:

- Up to 90% reduction in setup time

- Bearing capacity of up to 200 kg

- Repeatability accuracy of 0.005mm

- Positioning and clamping in one operation

These features are designed to ensure that once you set up a fixture, you can swap it in and out with ease, without losing the accuracy and consistency required for CNC machining.

Who Benefits from the 8-Hole Master Plate?

The 8-hole master plate is ideal for:

- Shops with high-mix parts: If you’re switching between different fixture types often, this system can streamline your workflow.

- Low-to-mid volume production: It’s perfect for environments where the production runs are smaller but still require fast fixture changes.

- Shops that need flexibility: If you’re working with a wide variety of parts that need different fixtures, this plate helps you switch easily without creating a bottleneck.

Key Considerations Before Adopting the 8-Hole Master Plate

While the 8-hole master plate offers many advantages, it’s important to ensure that your shop is ready for it. Standardization is crucial to making the most out of this system. All your fixtures should be compatible with either the 52×52mm or 96×96mm locating patterns, and you’ll need to keep your storage and organization consistent to avoid mixing up parts.

Bottom Line: Simplify Your CNC Workflow

The 8-hole master plate is an excellent solution for shops looking to manage mixed fixtures efficiently. It reduces setup time, improves repeatability, and increases workflow flexibility—all while ensuring that your fixtures remain secure and accurate. Whether you’re switching between different 5th axis vise chucks, or plates, this system is designed to make the process smoother and faster.

CTA: Ready to speed up your fixture changeovers and improve your CNC setup? Consider implementing the 8-hole master plate for a more streamlined, repeatable, and efficient workflow.