Modern CNC shops rarely finish a part on a single machine. A very common routing looks like this: rough on a high-power three-axis, move to a five-axis for multi-side finishing, then go to inspection, and sometimes back again for correction. This “multi-machine journey” is a smart way to use different assets for what they do best — but it introduces a quiet enemy: datum drift.

Datum drift is the slow erosion of accuracy that happens every time a part is re-clamped, transported, and re-located. Each move adds a small uncertainty. One move might add only a few microns. Two moves add more. By the third or fourth operation, the stack-up can push you out of tolerance, even if each individual machine is perfectly accurate.

This blog explains why datum drift shows up in cross-machine workflows, how to spot it early, and what a practical, production-friendly system looks like for keeping one datum alive across multiple CNCs.

Why cross-machine routing is growing (and why it’s risky)

Cross-machine routing is expanding for good reasons:

- Specialization of equipment. Roughing machines maximize removal. Finishing machines maximize precision.

- Shorter lead times. You parallelize work across cells instead of waiting on one machine.

- Higher mix. Different machines handle different geometries and setups more efficiently.

- Automation readiness. Pallet pools and robot cells naturally push work across stations.

But every handoff is a new chance to change the coordinate world. If your “zero” shifts between machines, you end up compensating with offset tweaks, hand-fitting, or rework. If a shop is constantly “chasing tolerance” after handoffs, this is almost always the mechanism underneath.

The physics of datum drift

Datum drift doesn’t require a catastrophic mistake. It comes from normal variation:

- Re-clamping changes seating.

Even if jaws close in the same spot, the part may seat differently on locators due to burrs, chips, or tiny geometry differences. - Interface inconsistency.

The fixture itself may not land in exactly the same place each time, especially if it bolts down manually. - Clamping distortion.

A part can deflect slightly under clamp load, then spring differently after the next op. - Human alignment variability.

Two operators can indicate the “same setup” with slightly different outcomes.

Each effect may look harmless alone. Together they create a drift trajectory: your datum slowly walks away from where CAM thinks it is.

The real cost of drift isn’t just scrap

Scrap is the obvious cost. But drift creates two more damaging costs:

- Schedule uncertainty.

If finishing ops always need tweaking, planners pad buffers and lead times. That reduces throughput even when parts pass. - Operator bandwidth.

Skilled people spend time correcting setups instead of preparing the next ones. Your best talent becomes a firefighting crew.

If you want cross-machine routing to increase capacity instead of increasing chaos, you need a datum-preservation system.

The goal: make the fixture carry the datum, not the machine

In strong cross-machine workflows, the work offset “lives” in the fixture, not in the machine table. That means:

- The part and its fixture act as a single calibrated unit.

- When the unit moves, the datum moves with it.

- Machines become interchangeable cutting stations.

This is the opposite of traditional thinking, where each machine “re-discovers” the datum through indicating. Traditional discovery is slow and variable. Datum-carrying fixtures are fast and repeatable.

Step 1: Standardize a repeatable docking baseline

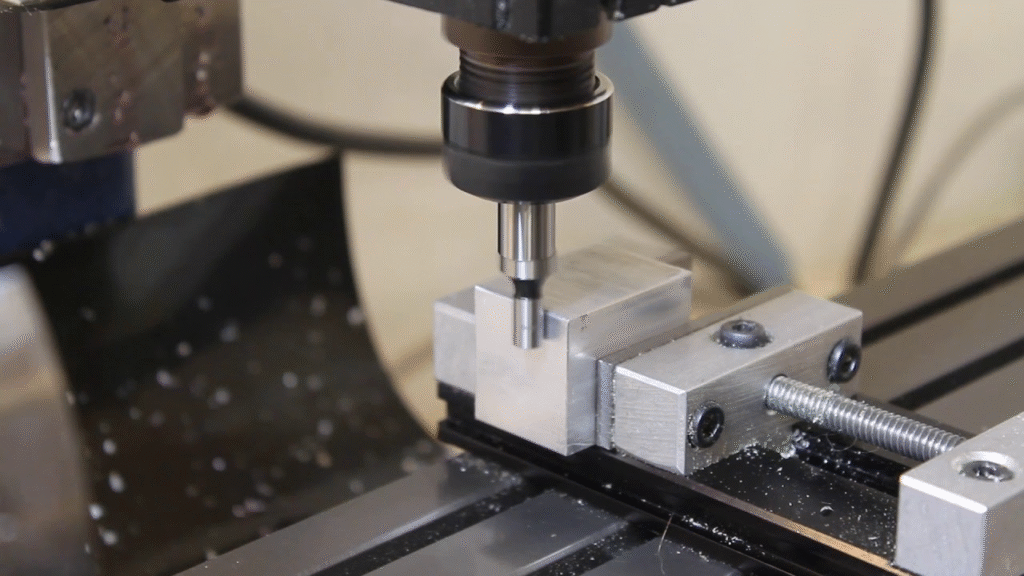

The biggest leap usually comes from standardizing how fixtures attach to machines. Instead of bolting everywhere and indicating every time, you create a repeatable docking baseline so the fixture locates itself mechanically.

Once the baseline is repeatable, a fixture can be removed from Machine A, moved to Machine B, and return to the same coordinate world without re-alignment. Many shops build this layer using modular zero-point quick-change families such as 3r systems, because the repeatability of the docking interface is what prevents datum loss during handoffs.

The important change is mental as much as mechanical: you stop treating fixtures as “things you align” and start treating them as “things that align themselves.”

Step 2: Control clamping repeatability at the part level

Even with a perfect docking baseline, drift creeps in if the part itself sits differently after each reclamp. If your workflow includes removing a part from its fixture and re-clamping it later, you need that reclamp to reproduce the same location.

Symmetric clamping helps here because it centers a part predictably without manual nudging. When jaws close evenly, the part is pulled toward a known midline instead of being pushed against a stop by human judgment. In many mixed-routing setups, a self-centering module like CNC Self Centering Vise is used to reduce clamping variance between machines, so the part location stays stable even when operations move around.

Again, the value is repeatability, not convenience. Automated centering is a datum-insurance policy.

Step 3: Separate roughing and finishing datums intentionally

A common hidden drift mistake is using the roughing datum for finishing. Roughing operations often tolerate more fixturing force and more localized deformation. Finishing operations do not.

A better approach:

- Rough with a datum that is easy to locate and stable under heavy load.

- Finish with a datum that is closer to functional geometry.

- If possible, keep the part in the same fixture family so the datum transfer is mechanical, not human.

This reduces the “spring-back surprise” where a roughing clamp distorts the part and creates unseen error for finish.

Step 4: Build an inspection loop that respects the datum

Inspection often breaks datum continuity without anyone noticing. If you remove the part from its fixture for inspection, then re-clamp it later, you’ve introduced a new datum reset. That’s fine if the clamping is truly repeatable — but dangerous if it is not.

Better options include:

- Inspect while the part remains in the fixture.

- Use locating features that match the machining datum.

- If you must reclamp, perform a quick verification probe before finishing.

Think of inspection as part of the same coordinate ecosystem, not a separate world.

How to diagnose datum drift in your shop

You likely have datum drift if you see these patterns:

- Finishing ops require frequent offset nudges after handoff.

- Re-runs from one machine to another show subtle mismatch.

- Parts pass on one machine but fail after transfer.

- Operators “trust their feel” more than the setup plan.

- The first part after transfer takes much longer than the rest.

If these are familiar, you don’t need more CAM tweaks. You need a stronger datum system.

Closing thought

Cross-machine routing is a powerful strategy for capacity and lead time — but only when your datum travels reliably. The winning formula is simple:

- Make fixtures dock repeatably across machines.

- Make part clamping reproduce location without judgment.

- Treat inspection as part of the same datum loop.

When those three pieces are in place, multi-machine workflows stop feeling risky. They become boring in the best way: consistent, fast, and predictable.